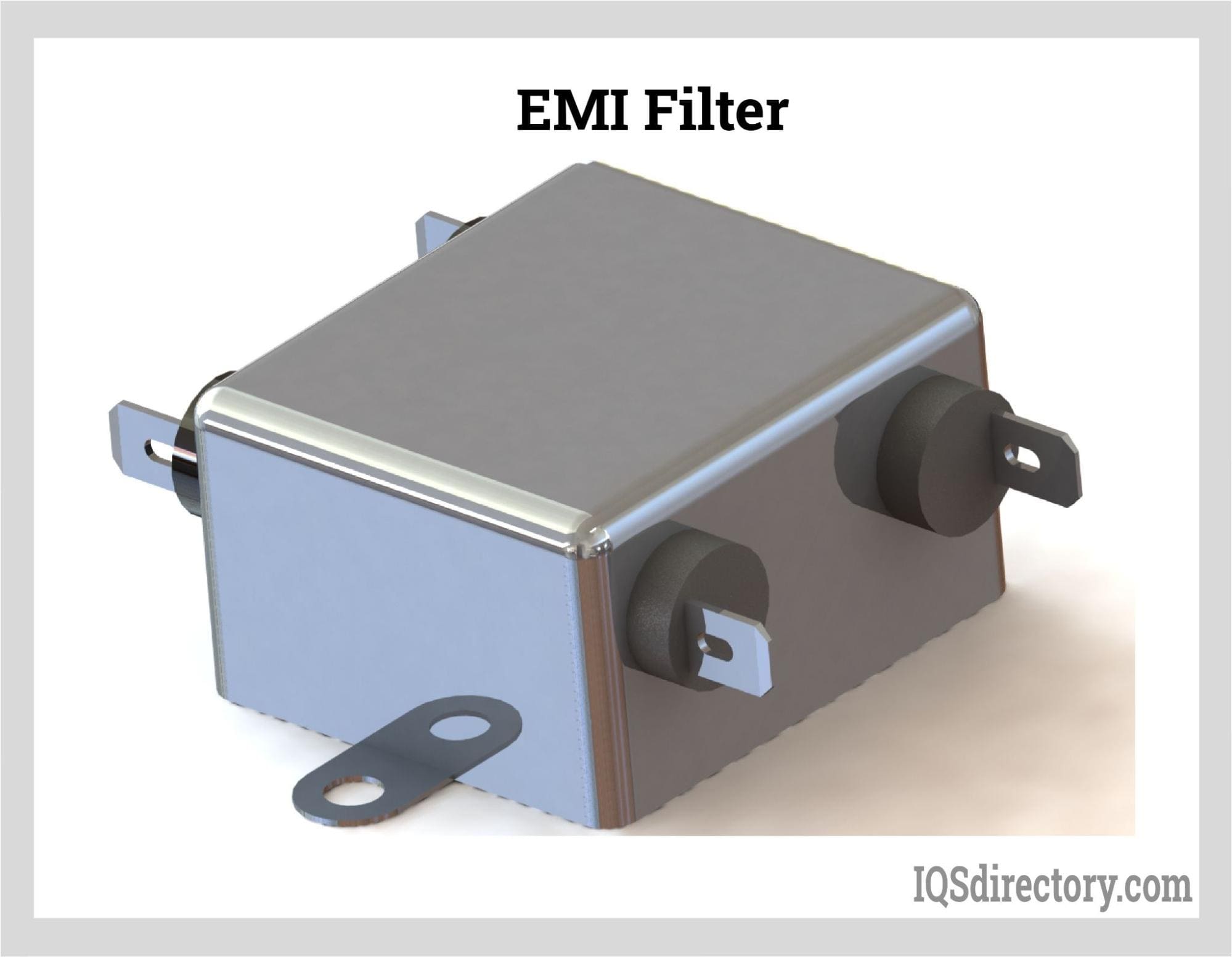

EMI filters, or Electromagnetic Interference filters, are electronic devices or components designed to suppress or filter electromagnetic interference (EMI) and radio frequency interference (RFI) from electrical circuits and electronic equipment. Read More…

TDK-Lambda Americas designs and manufactures a wide range of AC-DC and DC-DC power supplies and EMI Filters for Medical, Telecom, Industrial, Datacom, and Test & Measurement applications worldwide. The company has been a major provider of power solutions since 1948. TDK-Lambda is a subsidiary of the TDK Corporation, a leading global electronics company.

Our company offers a variety of standard and custom power supplies. These items are great for a wide range of applications. If you have any special requests then please let our representatives know. If you ever run into any questions or issues then our engineers are available to assist you. There is no project too challenging for our teams! Give us a call today!

For 4 decades, Acopian Power Supplies has specialized in long lasting power supplies (0 volts – 30000 V). We offer AC power supplies, DC power supplies, AC to DC converters, uninterruptible power supply (UPS), AC to DC power supplies & high voltage power supplies. With quality customer service & technical support, we have thousands of power supplies for thousands of applications.

APS are specialists in power conversion and the manufacture of high performance power systems. Products include power converters and inverters; motor drives and brakes; battery chargers; AC and DC power supplies; driver circuits and more. Custom and standard power systems are available.

At Quail Electronics, we are your power cord specialists. Our power supplies consist of green dot cords, high voltage cords, North American and international cords, specialty cords, plus adapters, plugs and strips.

More EMI Filter Manufacturers

EMI is unwanted electromagnetic radiation or electrical noise that can disrupt the proper functioning of electronic devices, communication systems, and other sensitive equipment. EMI filters are essential for reducing or eliminating this interference.

Industries That Use EMI Filters

Electromagnetic interference (EMI) filters are used in various industries to reduce or mitigate electromagnetic interference, which can disrupt the proper functioning of electronic devices and systems. Here are some of the industries where EMI filters are commonly employed:

Electronics and Telecommunications: EMI filters are widely used in consumer electronics, such as smartphones, laptops, and televisions, as well as in telecommunications equipment like cell towers and networking devices.

Aerospace and Defense: EMI filters are critical in aerospace and defense applications to ensure the reliable operation of sensitive electronics, communication systems, and radar equipment.

Medical Devices: Medical devices and equipment, such as MRI machines, pacemakers, and diagnostic equipment, use EMI filters to prevent electromagnetic interference that could affect patient safety or the accuracy of medical tests.

Automotive Industry: EMI filters are found in automotive electronics, including engine control units, infotainment systems, and safety features to ensure proper functioning and compliance with electromagnetic compatibility (EMC) standards.

Industrial Automation: EMI filters are used in manufacturing and industrial automation systems to protect sensitive control systems and sensors from interference and maintain operational reliability.

Renewable Energy: In wind turbines, solar inverters, and other renewable energy equipment, EMI filters are used to maintain the integrity and efficiency of power conversion and control systems.

Power Electronics: Power supply units, inverters, and motor drives in various industries employ EMI filters to reduce electromagnetic interference and meet EMC requirements.

Rail Transportation: EMI filters are used in train control systems, signaling systems, and onboard electronics to ensure safe and reliable operation.

Consumer Appliances: Household appliances like refrigerators, microwave ovens, and washing machines often include EMI filters to comply with EMC regulations and prevent interference with other electronic devices.

Data Centers: EMI filters are used in data center infrastructure, including servers, storage systems, and networking equipment, to maintain data integrity and prevent data corruption.

Audio and Broadcasting: In professional audio and broadcasting equipment, EMI filters are used to reduce interference and ensure the quality of audio and video signals.

Oil and Gas Industry: EMI filters are employed in oil and gas exploration and production equipment to safeguard control systems and sensors from electromagnetic interference in harsh environments.

Marine and Offshore Industry: EMI filters are used in marine vessels and offshore platforms to protect navigation and communication systems from interference.

Aviation: Aircraft systems and avionics rely on EMI filters to ensure the safe and reliable operation of electronic components.

Rail Transportation: EMI filters are used in trains and railway systems to ensure the safety and proper functioning of control and signaling equipment.

Choosing the Right EMI Filter Manufacturer

When choosing an EMI filter from an EMI filter manufacturer, it is important to compare at least 4 or 5 manufacturers using our list of EMI filter manufacturers. Each EMI filter manufacturer has a business profile page that highlights their areas of experience and capabilities, and has a contact form to directly communicate with the company for more information or request a quote. Review each EMI filter company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple EMI filter companies with the same quote.

Choosing the right EMI (Electromagnetic Interference) filter manufacturer is crucial to ensuring the proper functioning of your electronic equipment and compliance with regulatory standards. Here are some key factors to consider when making your selection:

EMI Filter Requirements: Define your specific EMI filter requirements, including frequency range, attenuation levels, and the types of interference you need to mitigate. Make sure the manufacturer can meet these requirements.

Industry Expertise: Look for manufacturers with experience and expertise in your industry or application. Different industries may have unique EMI filter requirements and standards.

Regulatory Compliance: Ensure the manufacturer's EMI filters comply with relevant industry standards and regulations (e.g., FCC, CE, IEC, or military standards). Ask for certifications and test reports.

Customization: Assess whether the manufacturer can provide custom EMI filter solutions tailored to your specific needs. Not all applications can be addressed with off-the-shelf filters.

Quality and Reliability: Research the manufacturer's reputation for producing high-quality and reliable EMI filters. Look for certifications like ISO 9001 to ensure consistent manufacturing processes.

Product Range: Check if the manufacturer offers a wide range of EMI filter products, including line filters, feedthrough filters, or power entry modules. A diverse product range can accommodate different applications.

Support and Technical Expertise: Evaluate the level of technical support and expertise the manufacturer can provide. They should be able to assist with filter selection, integration, and troubleshooting.

Lead Times and Delivery: Consider the manufacturer's lead times and ability to meet your delivery schedule. A reliable supply chain is crucial to your production timelines.

Price and Cost Considerations: While cost is important, it shouldn't be the sole consideration. Quality, performance, and compliance should take precedence. However, it's still essential to compare pricing and value for your specific needs.

Vendor Reputation and Reviews: Look for reviews, testimonials, and case studies related to the manufacturer. A strong reputation can indicate customer satisfaction and reliable products.

Warranty and Support Services: Inquire about the warranty offered with the EMI filters. Also, consider the availability of post-sale support services, such as troubleshooting and repairs.

Scalability: If you anticipate changes in your EMI filter requirements or an increase in production volume, choose a manufacturer with the scalability to meet your evolving needs.

Environmental Considerations: Depending on your industry or application, you may need EMI filters that can withstand extreme environmental conditions. Ensure the manufacturer's products are suitable for your operating environment.

Long-Term Relationship: Consider whether you want to establish a long-term relationship with the manufacturer. Consistency and reliability in your supply chain can be valuable in the long run.

Remember that EMI filters play a critical role in ensuring the electromagnetic compatibility (EMC) of your electronic devices and can impact their overall performance. Take the time to research and evaluate potential manufacturers thoroughly to make an informed decision that aligns with your project's specific requirements and goals.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures Membrane Switches

Membrane Switches Power Cords

Power Cords Power Supplies

Power Supplies Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services