Programmable power supplies, often referred to as programmable DC power supplies or simply programmable supplies, are electronic devices used in various industries and applications to provide a controlled and adjustable source of direct current (DC) voltage and current. Read More…

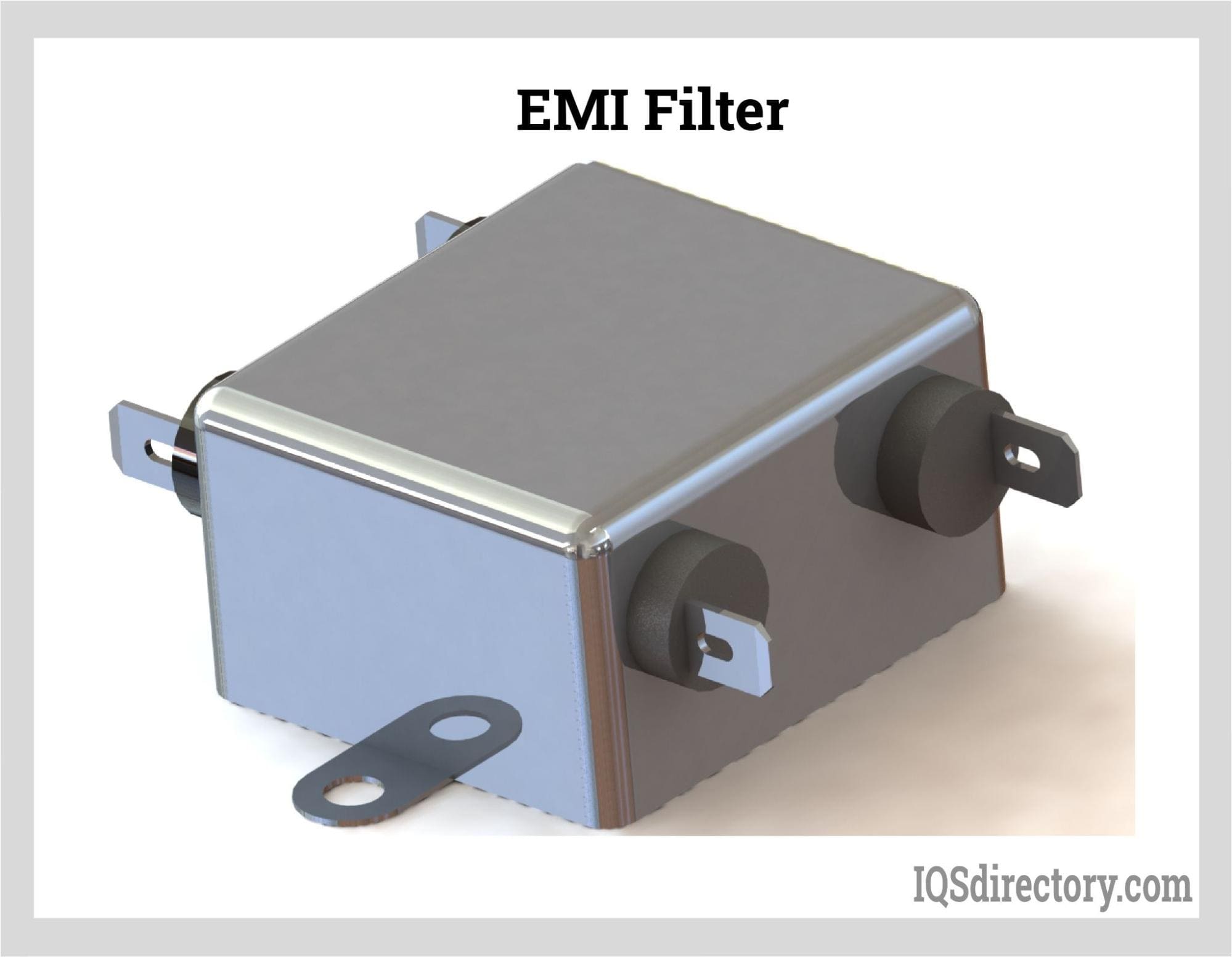

TDK-Lambda Americas designs and manufactures a wide range of AC-DC and DC-DC power supplies and EMI Filters for Medical, Telecom, Industrial, Datacom, and Test & Measurement applications worldwide. The company has been a major provider of power solutions since 1948. TDK-Lambda is a subsidiary of the TDK Corporation, a leading global electronics company.

Our company offers a variety of standard and custom power supplies. These items are great for a wide range of applications. If you have any special requests then please let our representatives know. If you ever run into any questions or issues then our engineers are available to assist you. There is no project too challenging for our teams! Give us a call today!

For 4 decades, Acopian Power Supplies has specialized in long lasting power supplies (0 volts – 30000 V). We offer AC power supplies, DC power supplies, AC to DC converters, uninterruptible power supply (UPS), AC to DC power supplies & high voltage power supplies. With quality customer service & technical support, we have thousands of power supplies for thousands of applications.

APS are specialists in power conversion and the manufacture of high performance power systems. Products include power converters and inverters; motor drives and brakes; battery chargers; AC and DC power supplies; driver circuits and more. Custom and standard power systems are available.

At Quail Electronics, we are your power cord specialists. Our power supplies consist of green dot cords, high voltage cords, North American and international cords, specialty cords, plus adapters, plugs and strips.

More Programmable Power Supply Manufacturers

These power supplies are designed to be versatile and adaptable to meet the specific requirements of different testing, research, and manufacturing processes.

Applications of Programmable Power Supplies

Programmable power supplies are essential tools in a variety of industries, allowing for precise voltage and current regulation. Here are some of the most common applications for programmable power supplies:

Electronics Manufacturing: Programmable power supplies are widely used in electronics manufacturing for testing and powering electronic components and devices. They help ensure consistent and accurate voltage and current levels during the testing and quality control processes.

Automotive Industry: Programmable power supplies play a crucial role in the automotive industry for testing and simulating electrical systems in vehicles. They are used to verify the performance of components such as sensors, actuators, and control units.

Aerospace and Defense: In the aerospace and defense sector, programmable power supplies are essential for testing and calibrating avionics, communication systems, and radar equipment. They provide precise and stable power sources for critical applications.

Renewable Energy: Programmable power supplies are used in the renewable energy sector for research, development, and testing of solar panels, wind turbines, and energy storage systems. They enable engineers to simulate various operating conditions and evaluate system performance.

Research and Development (R&D): Across various industries, R&D laboratories employ programmable power supplies for prototyping, experimentation, and product development. These power supplies offer flexibility and precision for researchers working on a wide range of projects.

Advantages and Benefits of Programmable Power Supplies

Programmable power supplies offer several benefits in various applications, particularly in electronics testing, research, and development. Here are some of the key advantages of using programmable power supplies:

Versatility: Programmable power supplies are highly versatile and can provide a wide range of output voltages and currents. This versatility makes them suitable for testing a wide variety of electronic devices, from low-power sensors to high-power amplifiers.

Precise Control: These power supplies allow for precise control of voltage and current levels. Users can set the desired output values with high accuracy, ensuring that the device under test receives the required power without the risk of overvoltage or overcurrent.

Programmability: The ability to program voltage and current levels using a computer interface or built-in programming language makes it easy to automate testing procedures. This is especially useful for repetitive or complex test sequences.

Remote Operation: Many programmable power supplies can be controlled remotely through interfaces such as USB, Ethernet, or GPIB (General Purpose Interface Bus). This enables users to monitor and adjust power supply settings from a distance, making it suitable for remote testing and monitoring applications.

Safety Features: Programmable power supplies often come with built-in safety features, such as overvoltage and overcurrent protection, to prevent damage to both the device under test and the power supply itself. These safeguards can help reduce the risk of accidents and equipment damage.

Data Logging and Monitoring: Some programmable power supplies offer data logging capabilities, allowing users to record voltage and current measurements over time. This data can be valuable for analyzing device behavior, identifying issues, and documenting test results.

Efficiency: Many modern programmable power supplies are designed to be highly efficient, minimizing energy waste and heat generation. This can lead to cost savings in terms of energy consumption and reduced cooling requirements.

Protection and Diagnostics: Some programmable power supplies offer diagnostic features that can help identify and troubleshoot problems in the device under test. These features may include fault detection, waveform generation, and voltage/current profiling.

Customization: Users can often customize the behavior of programmable power supplies to suit their specific testing needs, whether it involves creating complex voltage waveforms or implementing specific control algorithms.

Cost Savings: While programmable power supplies may have a higher upfront cost compared to basic fixed-voltage supplies, their versatility and automation capabilities can lead to cost savings in the long run by reducing testing time and improving efficiency.

How to Select a Programmable Power Supply Manufacturer

When choosing a programmable power supply from a programmable power supply manufacturer, it is important to compare at least 4 or 5 manufacturers using our list of programmable power supply manufacturers. Each programmable power supply manufacturer has a business profile page that highlights their areas of experience and capabilities, and has a contact form to directly communicate with the company for more information or request a quote. Review each programmable power supply company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple programmable power supply companies with the same quote.

When choosing a programmable power supply manufacturer, there are several important factors to consider to ensure that you select a reliable and suitable supplier for your specific needs. These factors include:

Specifications and Features: Review the technical specifications and features of the programmable power supplies offered by the manufacturer. Consider factors such as voltage and current ranges, resolution, accuracy, and the number of output channels. Ensure that the specifications meet your application requirements.

Quality and Reliability: Assess the manufacturer's reputation for quality and reliability. Look for certifications such as ISO 9001 or other industry-specific certifications that demonstrate their commitment to producing high-quality products.

Customer Support: Evaluate the level of customer support provided by the manufacturer. This includes pre-sales support, technical support, and post-sales support. Reliable customer support can be crucial when you encounter issues or need assistance with your programmable power supply.

Product Warranty: Check the warranty terms offered by the manufacturer. A longer and more comprehensive warranty can provide you with peace of mind in case of product failures or defects.

Compatibility: Ensure that the power supply is compatible with your existing equipment and instrumentation. Compatibility with standard communication protocols (e.g., USB, LAN, GPIB) can simplify integration.

Safety Features: Pay attention to the safety features of the power supply, such as overvoltage protection, overcurrent protection, and short-circuit protection. Safety should be a top priority, especially when working with sensitive or expensive equipment.

Customization Options: If your application requires specific customizations or modifications to the power supply, discuss these options with the manufacturer to ensure they can meet your needs.

By carefully considering these factors, you can choose a programmable power supply manufacturer that aligns with your specific requirements.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures Membrane Switches

Membrane Switches Power Cords

Power Cords Power Supplies

Power Supplies Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services